Materials Test Lab Sparkle: Decoding Quality with Expertise

Wiki Article

Placing Products to the Test: Discovering the Duty of Products Examination Labs

Products examination laboratories play a critical duty in making sure the high quality and integrity of numerous materials made use of in markets such as construction, aerospace, and production. These laboratories conduct extensive testing to evaluate the efficiency, stamina, toughness, and safety and security of materials, making it possible for companies to make educated choices about their use in products and frameworks. Through a mix of innovative strategies and specific tools, materials examination laboratories have the ability to examine the buildings of metals, polymers, composites, and various other products under different problems and stressors. The outcomes gotten from these examinations supply beneficial understandings into product habits, permitting designers and designers to enhance their items and processes. This write-up will explore the importance of materials testing, the sorts of products checked, screening methods and devices made use of, as well as the applications of materials examination results. Furthermore, it will talk about future trends in materials testing, highlighting the continuous improvements in this field.Significance of Products Screening

Consistently evaluating the quality of materials is important in making certain the integrity and safety of products in numerous sectors. This is where products screening plays an important duty. Products testing involves subjecting materials to numerous examinations and experiments to review their mechanical, physical, and chemical residential or commercial properties. By performing these examinations, providers and suppliers can make sure that their products satisfy the called for requirements and requirements.One of the essential factors why materials testing is vital is the guarantee of product high quality. With strenuous screening, suppliers can identify any type of defects or weak points in the products made use of for their items.

By subjecting products to various examinations, producers can identify their strength, resistance, and sturdiness to outside elements such as heat, stress, or chemicals. Whether it is automobile components, medical gadgets, or construction products, products testing aids in determining any type of possible safety hazards and creating appropriate actions to alleviate them.

Types of Materials Tested

Various kinds of products are examined in products test labs to examine their mechanical, physical, and chemical residential or commercial properties. These materials can encompass a variety important, including steels, polymers, porcelains, composites, and also natural products such as timber and concrete.Metals are generally tested because of their widespread use in different industries. These examinations examine properties such as tensile strength, firmness, and ductility. Polymers, on the various other hand, are tested to establish their flexibility, thermal stability, and resistance to chemicals. Ceramics are analyzed for their brittleness, toughness, and resistance to high temperature levels. Composites, which contain two or even more various products, are reviewed to understand their general efficiency, including aspects like durability, strength, and adaptability.

All-natural materials like wood are tested to analyze their strength, dampness web content, and resistance to degeneration (materials test lab). Concrete is another generally tested product, with tests concentrating on its compressive stamina, durability, and resistance to ecological aspects

Along with these materials, materials test labs also examine layers, paints, adhesives, and different other products utilized in building and construction, manufacturing, and other industries. By subjecting these products to strenuous screening, scientists and designers can gather beneficial data to notify product selection, layout optimization, and quality assurance processes.

Examining Strategies and Tools

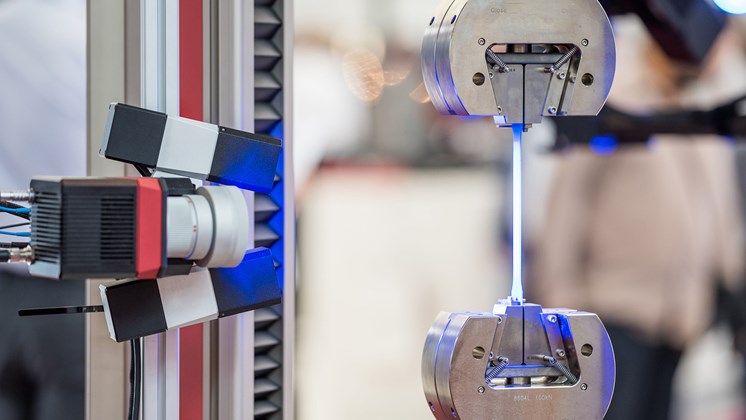

Evaluating techniques and equipment play a critical role in products examination laboratories for reviewing the mechanical, physical, and chemical buildings of various products. These strategies and devices are essential in guaranteeing the quality, dependability, and security of materials utilized in different industries such as aerospace, automobile, building and construction, and clinical.One generally utilized screening strategy in products test laboratories is mechanical screening, which includes subjecting products to different forces or lots to identify their toughness, solidity, ductility, and published here various other mechanical homes. This is frequently done using equipment such as universal testing makers, which can use tensile, compressive, and bending pressures to check specimens.

Physical screening strategies are also used to examine properties such as thickness, thickness, thermal conductivity, and electric conductivity. Devices such as thickness meters, viscometers, thermal conductivity analyzers, and electric conductivity meters are utilized to do these tests accurately.

Chemical screening methods are used to identify the chemical make-up and pureness of products. Strategies such as mass, chromatography, and spectroscopy spectrometry are generally made use of, together with specific tools developed for these objectives.

Applications of Materials Examination Outcomes

The outcomes of products evaluating give beneficial understandings into the performance and suitability of different products for specific applications in numerous sectors - materials test lab. These test results play an important role in establishing the high quality, durability, and safety and security of products made use of in manufacturing proceduresClick This Link One of the essential applications of products test results is in the area of building. Engineers and engineers rely upon these outcomes to select suitable products for constructing structures, such as bridges, high-rise buildings, and household buildings. By conducting tests on products like hardwood, steel, and concrete, they can ensure that these products satisfy the called for standards and can hold up against various ecological problems.

In the aerospace sector, materials examination results are important in determining the viability of products for aircraft elements. By subjecting products to strenuous screening, designers can analyze their mechanical homes, resistance to heat and corrosion, and capability to stand up to high-stress problems. This information is important in guaranteeing the safety and dependability of airplane.

Future Fads in Products Testing

In the realm of products testing, innovations in materials testing approaches are forming the trajectory of the area, ushering in a brand-new age of technology and accuracy. One future pattern in products testing is the combination of fabricated knowledge (AI) and machine understanding algorithms right into testing processes. These approaches allow for the evaluation of product homes without triggering damage or modification to the example, making them suitable for examining irreplaceable or useful products.Conclusion

In conclusion, products testing plays a vital role in different industries by making certain the top quality, safety, and performance of materials utilized in items and frameworks. The outcomes gotten from materials screening are made use of to make educated choices in product selection, production, and layout procedures.With a combination of advanced strategies and specialized devices, materials test laboratories are able to evaluate the buildings of metals, polymers, compounds, and various other materials under different problems and stress factors. By performing examinations on products like concrete, steel, and wood, they can ensure that these products fulfill the called for requirements and can withstand numerous ecological conditions.

In the aerospace industry, products examination results are important in identifying the suitability of products for aircraft elements. By testing products for their adaptability, strength, and resistance to influence, producers can select the most appropriate materials for different automotive elements, such as body panels, engine components, and safety functions.In the world of materials screening, innovations in materials evaluating techniques are shaping my review here the trajectory of the field, ushering in a brand-new period of technology and precision.

Report this wiki page